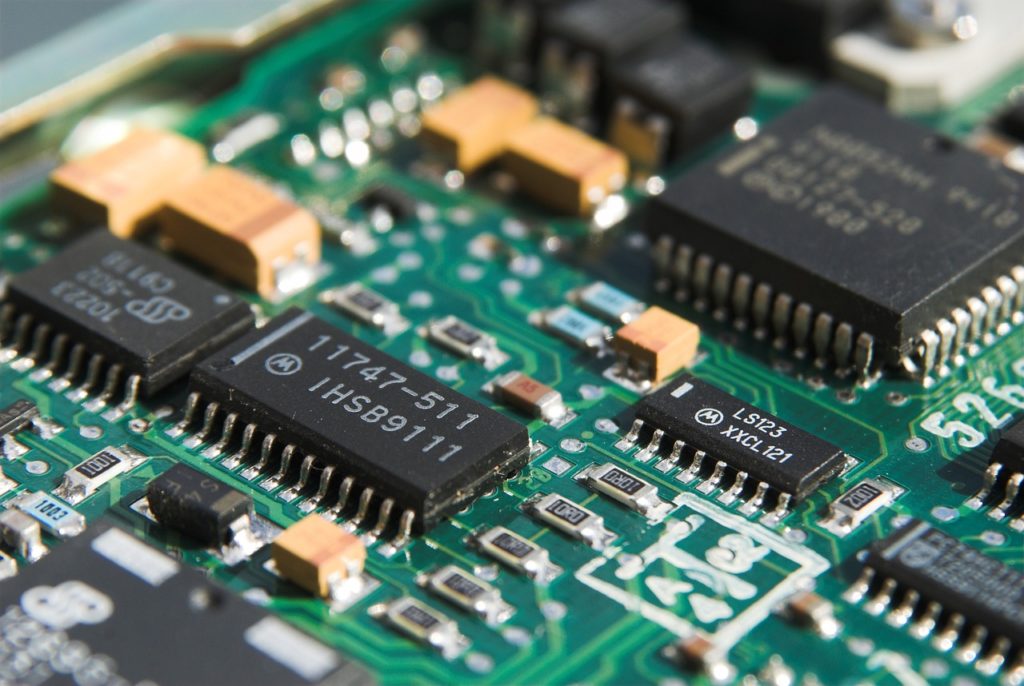

Designing your own printed circuit board is an inventive process and can give you a great head start in the manufacturing process. However, you may find yourself choosing between a rigid and a flexible circuit board. Why not choose both? You need a rigid flex PCB. Keep reading to find out more about this type of PCB.

What is a Rigid Flex PCB?

A Rigid Flex PCB combines the flexible inner layers of a multilayer flexible circuit board with the rigid outer layer of a multilayer rigid one. They really bring together the best of both worlds. Allowing for higher component density and higher quality control, they are excellent for designs which need both a little sturdiness and a little flexibility.

Weight Benefits

Since you can pack multiple components into one small space, there are many benefits to choosing a rigid flex PCB. Many companies already utilize a rigid flex PCB for this reason. For example, you will frequently find it used in devices like pacemakers and military equipment where both size and weight are an issue. If you need a circuit board which is going to fit in a smaller area but still delivers the same high-quality results, rigid flex might be the answer you are looking for.

More Challenging a Design

One of the downsides of rigid flex pcbs is that they are slightly more difficult to design than one of their counterparts. However, if you think you are up to taking on the rigid flex pcb manufacturing process, it might be an excellent challenge for you. There are multiple resources out there to guide you and you an even make use of design software such as Altium which supports rigid flex. It will result in a much higher quality design which will no doubt serve you better than one of its alternatives.

Less Likely to Fault

One of the key reasons to choose a rigid flex PCB is that they make for higher quality and less likely to fault design. This is due to the fact that there are fewer interconnections and cables. Faults are therefore greatly reduced. The test conditions are also much more simplified. If you are looking for a solution which allows you to properly test the circuit board before installation, this design will allow you to do. By being able to test pre-installation, you will majorly cut down on time and resources potentially spent conducting extra tests. You won’t need to spend money on many different prototypes, just on potentially reprinting the circuit board if need be.

Printed circuit boards are one of the most important components we use in the modern world. If you are interested in expanding your technological horizons, you should definitely consider looking into designing and manufacturing PCBs. Learning about the different types of PCBs available to you, and the advantages and disadvantages of all of them, can only help you to become a better designer. Rigid Flex PCBs are great for a whole variety of different reasons. If you think you need a circuit board which is flexible enough for your wider design but strong enough to withstand anything you can throw against it, this is definitely for you.

wonderful article and thanks for sharing